What Is MDF? | How MDF Is Made | Is MDF Dangerous?

Posted by Lee Watkinson on 14th Mar 2023

What is MDF?

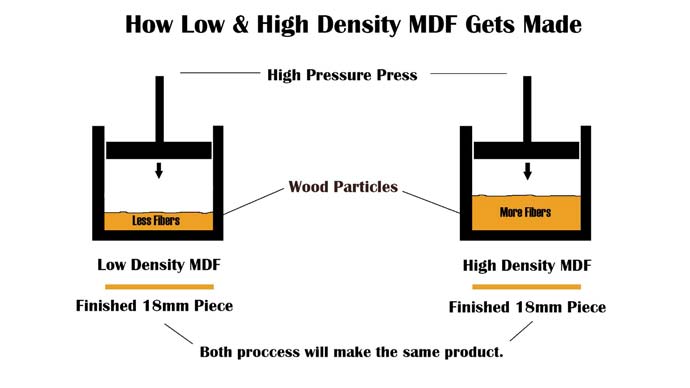

Medium Density Fiberboard, commonly known as MDF, is an engineered wood product made by combining wood fibers and adhesive under high pressure and temperature. The resulting panel has a smooth and uniform surface, with no knots or grain patterns. MDF is available in various thicknesses, ranging from 1/8 inch to 1 inch, and can be cut-to-size, drilled, and routed easily.

MDF is composed of small wood fibers, typically sourced from softwood species such as pine or spruce, that are broken down into individual strands. These strands are then mixed with resin, wax, and other chemicals to create a homogenous mixture. The mixture is then pressed and heated, using high pressure and temperature, to form a solid panel.

One of the key benefits of MDF is its consistency in density and thickness, making it a reliable material for precision woodworking projects. Additionally, MDF can be sanded and painted easily, offering a smooth and uniform finish. However, it's important to note that MDF is not waterproof and can swell and break down when exposed to moisture.

In comparison to other engineered wood products, such as particleboard or plywood, MDF has a denser composition, making it stronger and more durable. MDF also has a lower tendency to split or crack, making it a popular choice for furniture-making, cabinetry, and other woodworking applications.

Properties of MDF

MDF has several properties that make it an attractive material for woodworking projects. These properties include its density, strength, and durability.

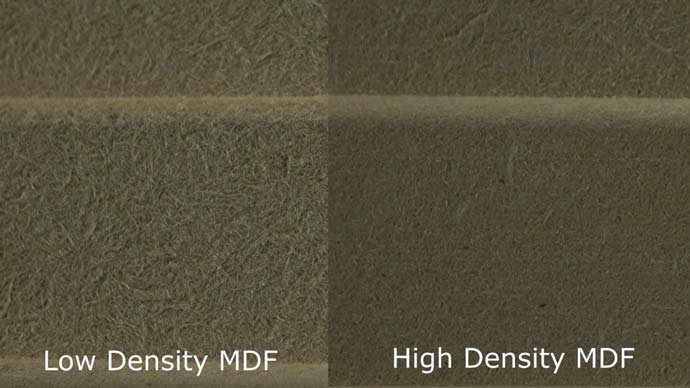

1. Density: MDF has a higher density than many other engineered wood products, such as particleboard. This means that it is more resistant to dents and scratches, making it a more durable option for furniture-making and other woodworking projects.

2. Strength: MDF is a strong and stable material that can hold screws and nails well, making it a popular choice for cabinetry and other construction applications. Additionally, its dense composition makes it less likely to split or crack when drilled or cut.

3. Durability: MDF is a long-lasting material that can withstand wear and tear over time. Its uniform composition makes it less susceptible to warping, twisting, or cupping, which can be a concern with solid wood.

However, it's important to note that some MDF has limitations when it comes to its properties. One of the main drawbacks of lower quality MDF is its susceptibility to moisture damage. If exposed to water or high humidity, MDF can swell and break down, making it unsuitable for outdoor use or in areas with high moisture content, such as bathrooms or kitchens. However, our MDF does not suffer from these drawbacks, as we supply the highest quality moisture-resistant HDF for our skirting boards, architraves and interior trims.

Overall, MDF has several properties that make it a popular material for woodworking projects, including its density, strength, and durability. However, the susceptibility of lower quality MDF to moisture damage and potential health risks should be taken into consideration when deciding whether to use MDF for a particular project.

Types of MDF

- Standard MDF: This is the most commonly used type of MDF and is available in different thicknesses and sizes. It has a smooth surface and is ideal for painting, laminating, or veneering.

- Moisture-resistant MDF: This type of MDF has a higher resistance to moisture and can be used in areas where regular MDF would not be suitable, such as in kitchens, bathrooms, or other high-moisture environments. Moisture-resistant MDF is also easier and safer to clean with water and cleaning products.

- Fire-retardant MDF: Fire-retardant MDF is treated with special chemicals that make it resistant to fire. It is commonly used in commercial and public buildings where fire safety is a concern.

- Ultralight MDF: Ultralight MDF is a lightweight version of MDF that is easier to handle and transport. It is ideal for use in applications where weight is a concern, such as in RVs or boats.

- High-density MDF: High-density MDF is denser than standard MDF and has a smoother surface, making it ideal for applications where a high-quality finish is required.

These are just a few examples of the types of MDF that are available. The type of MDF that is best for your project will depend on your specific needs and requirements. It is always a good idea to consult with a professional woodworker or supplier to help you choose the right type of MDF for your project.

Uses of MDF

MDF is a versatile material that can be used in a variety of woodworking projects. Some of the most common uses of MDF include:

- Skirting Boards: MDF is the most popular choice for skirting boards, our high quality moisture-resistant HDF is ideal for fitting skirting boards in every room.

- Furniture-making: MDF is a popular choice for making furniture, particularly pieces that will be painted or laminated. Its smooth and consistent surface allows for a clean finish, and it can be easily shaped and routed to create intricate designs and patterns.

- Cabinetry: MDF is often used for making cabinets, including kitchen cabinets, bathroom vanities, and storage cabinets. Its strength and stability make it a reliable material for cabinetry, and its uniform composition allows for precise cuts and joinery.

- Architraves: Like skirting boards, architraves are a necessary part of any room (if it has doors), MDF provides the greatest versatility for creating a clean and smooth finish for doorways.

- Wall panels: MDF can be used to create decorative wall panels, either as a standalone design feature or as a substrate for tiles or other materials. Its density and stability make it suitable for wall panels that will be exposed to wear and tear.

- Mouldings: MDF is a popular choice for making decorative mouldings, such as skirting boards, crown mouldings, and trims. Its uniform density and ability to hold intricate shapes make it a versatile option for creating a variety of moulding styles.

- DIY projects: MDF is a popular material for DIY enthusiasts who want to create their own woodworking projects. It is affordable, easy to work with, and can be used for a variety of applications, from shelves and storage units to picture frames and decorative objects.

Overall, MDF is a versatile and popular material for a wide range of woodworking projects. Its affordability, versatility, and consistency make it an attractive option for DIY enthusiasts and professional woodworkers alike.

Advantages and Disadvantages of MDF

Advantages of MDF

- Affordability: MDF is a cost-effective option for woodworking projects compared to solid wood, making it a popular choice for DIY enthusiasts and professional woodworkers alike.

- Versatility: MDF can be easily cut, shaped, and routed, making it a versatile material for a wide range of applications. It can be painted, laminated, or veneered to create a variety of finishes and styles.

- Consistency: MDF has a uniform density and thickness, making it a reliable material for precision woodworking projects. It is less likely to have knots or other irregularities that can affect the quality of the finished product.

- Sustainability: MDF is an environmentally friendly option, as it is made from recycled wood fibers and can be recycled at the end of its lifespan.

Disadvantages of MDF

- Moisture Damage: Standard MDF is not water-resistant and can swell and deteriorate when exposed to moisture. This limits its use in areas with high humidity or moisture content, such as bathrooms or kitchens.

- Formaldehyde Emissions: MDF can release formaldehyde, a potential carcinogen, which can pose health risks if proper safety measures are not taken during handling and processing.

- Limited Strength: While MDF is a strong and stable material, it is not as strong as solid wood or other engineered wood products, such as plywood. It may not be suitable for applications that require high strength or load-bearing capacity.

- Difficulty in Joinery: MDF can be challenging to join with screws, nails, or other fasteners due to its density and tendency to split. Special care must be taken when joining MDF to avoid damaging the material.

In summary, MDF has several advantages that make it a popular material for woodworking projects, including its affordability, versatility, consistency, and sustainability. However, it also has some disadvantages, such as susceptibility to moisture damage, formaldehyde emissions, limited strength, and difficulty in joinery. Understanding these advantages and disadvantages can help woodworkers and DIY enthusiasts make informed decisions about whether MDF is the right material for their projects.

MDF vs. Plywood

MDF and plywood are both engineered wood products that are commonly used in woodworking and construction. Here are some of the key differences between the two.

- Material composition: MDF is made from wood fibers that have been bonded together with resin and then pressed into sheets. Plywood, on the other hand, is made from thin sheets of wood veneer that have been glued together.

- Strength and durability: Plywood is generally stronger and more durable than MDF, making it a better choice for applications where strength is important. However, MDF can be more resistant to warping and cracking than plywood.

- Surface finish: MDF has a smooth and consistent surface that is ideal for painting, laminating, or veneering. Plywood has a more natural and textured surface that may require sanding or filling before finishing.

- Moisture resistance: Plywood is generally more moisture-resistant than MDF, making it a better choice for use in areas that are prone to moisture, such as kitchens or bathrooms.

- Cost: MDF is generally less expensive than plywood, making it a popular choice for budget-conscious projects.

Ultimately, the choice between MDF and plywood will depend on the specific needs of your project. MDF is a good choice for applications where a smooth surface and low cost are important, while plywood is better suited for applications where strength and durability are a priority.

MDF is a popular material with a wide range of uses and benefits. While it has its drawbacks, MDF is a cost-effective and versatile option for many woodworking projects. Understanding the properties and characteristics of MDF can help woodworkers and DIY enthusiasts make informed decisions about which materials to use for their projects

Frequently Asked Questions

What is MDF?

MDF is a type of engineered wood made from wood fibers, resin, and wax. It is a versatile and popular material for a wide range of woodworking projects.

What is MDF made from?

MDF is made from wood fibers, which are often sourced from waste wood or sawdust. The fibers are mixed with a resin and wax mixture to create a consistent and uniform material.

What is MDF used for?

MDF has a wide range of applications, including furniture-making, cabinetry, wall panels, moldings, and DIY projects. Its affordability, versatility, and consistency make it a popular choice for both professional woodworkers and DIY enthusiasts.

What does MDF stand for?

MDF stands for Medium Density Fiberboard, which refers to the density of the material and the way it is made. MDF is denser than particleboard but less dense than solid wood.

How is MDF made?

MDF is made by breaking down wood fibers into small particles and combining them with a resin and wax mixture. The mixture is then pressed and formed into boards under high temperature and pressure, resulting in a smooth and consistent surface.

Is MDF dangerous?

MDF can release formaldehyde, a potential carcinogen, which can pose health risks if proper safety measures are not taken during handling and processing. It is important to follow safety guidelines when working with MDF to minimize the risk of exposure to formaldehyde. Additionally, MDF is not water-resistant and can swell and deteriorate when exposed to moisture, which can limit its use in certain applications. Despite these drawbacks, MDF remains a popular and affordable material for a wide range of woodworking projects. We have a whole post regarding the safety of MDF - there should be no cause for concern when it comes to our MDF products!

Is MDF banned?

No, MDF is not banned. However, some types of MDF may contain formaldehyde, a chemical that can be harmful if it is inhaled in large quantities. To address this issue, some countries have introduced regulations to limit the amount of formaldehyde that can be used in MDF production. Additionally, some manufacturers have started producing low-emission or formaldehyde-free MDF products to meet consumer demand for safer and more sustainable products. It's always a good idea to check the formaldehyde emissions rating of MDF products before purchasing and using them, especially if you or someone in your household has respiratory issues.

Lee Watkinson

Digital Marketing Director at Skirting World with 10 years of experience in Home Interiors & Manufacturing.