HDF vs MDF | High-Density Fibreboard | Engineered Board Comparison

Posted by Skirting World on 4th Sep 2025

HDF and MDF are both engineered wood boards made from compressed wood fibres, but their different densities create sheets suited for completely different construction purposes. Learn how to understand these differences to help select the right meterial for your project.

Quick answer: HDF packs more fibres into a denser, stronger board ideal for flooring and high-wear applications. MDF offers easier workability and takes paint beautifully, making it perfect for furniture and interior mouldings.

What are HDF and MDF?

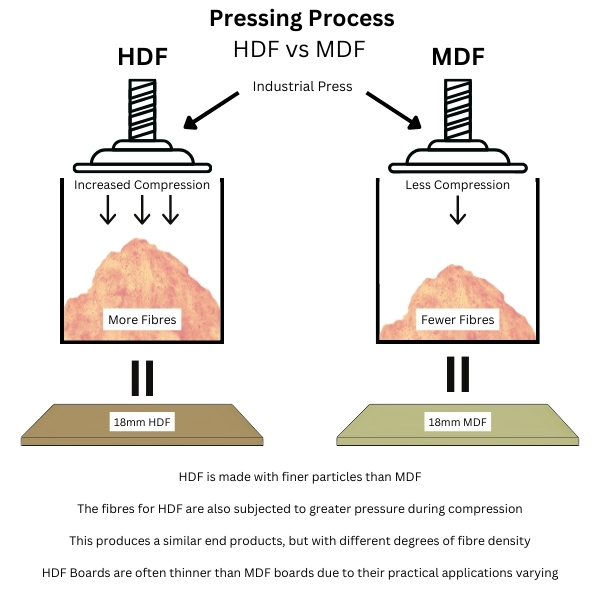

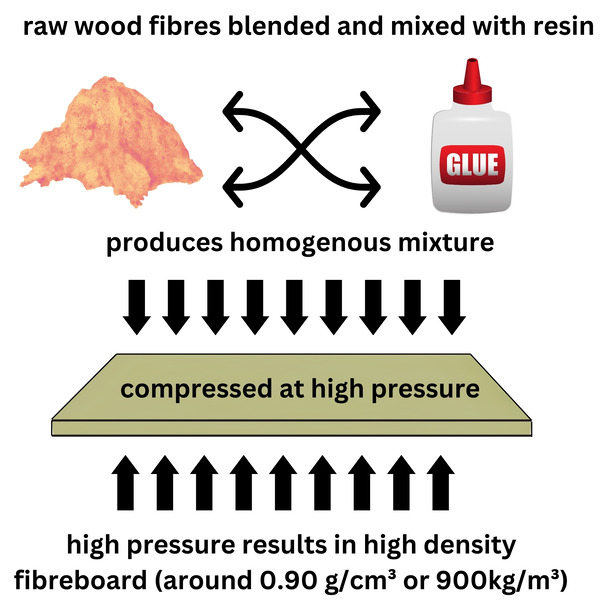

Both HDF (High-Density Fibreboard) and MDF (Medium-Density Fibreboard) are engineered wood boards made from wood fibres, resin, and wax pressed together under heat and pressure. They both start from the same ingredient - wood fibres, but the fundamental difference lies in how tightly these fibres are compressed.

Think of it like comparing a loosely packed snowball to one you've really compressed - same basic ingredients, but the density changes everything about how they perform.

HDF (High-Density Fibreboard)

Density: 800-1040 kg/m³

Uses finer wood fibres compressed at higher pressures, creating a harder, stronger board. Often called hardboard, it's commonly used as a substrate for laminate flooring and in applications requiring superior durability.

MDF (Medium-Density Fibreboard)

Density: 680-730 kg/m³

Uses standard wood fibres with moderate compression, creating a workable material that machines beautifully. Widely used in furniture making, skirting boards, and applications where detailed machining is required.

Recap: HDF & MDF typically start with softwood fibres from pine, fir, or spruce. The manufacturing process - particularly the pressure and temperature used -determines their different properties.

The density difference

HDF packs about 30% more material into the same space as MDF. Where MDF typically weighs around 700-750 kg per cubic metre, HDF comes in at 850-1000 kg per cubic metre.

This extra density comes from using finer wood fibres, more resin (up to 20% versus MDF's typical 10-15%), and much higher pressing pressures during manufacturing.

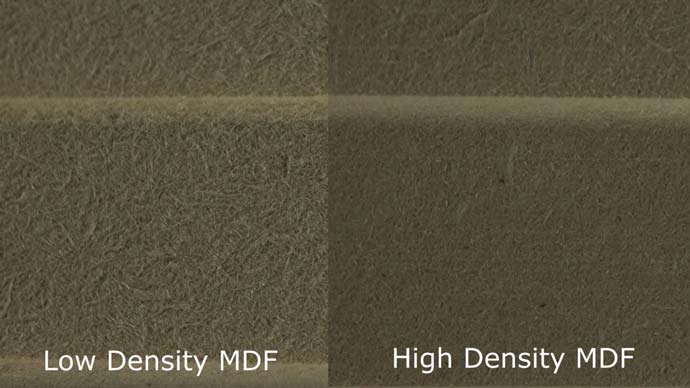

The density difference affects performance from strength to moisture resistance to how the materials behave when you work with them. HDF's tighter fibre structure creates a harder surface that resists wear and impact better, whilst MDF's more open structure makes it easier to machine and shape.

Practical differences

| Property | HDF | MDF |

|---|---|---|

| Internal bond strength | 1.8 N/mm² | 0.60 N/mm² |

| Screw holding | Superior - roughly 3x better | Good for most applications |

| Moisture resistance | Better dimensional stability | Can swell 11% when soaked |

| Workability | Harder to cut and shape | Excellent for detailed work |

| Available thicknesses | Limited to 3-8mm typically | 3mm to 38mm or more |

HDF's strength and moisture resistance make it ideal where durability matters most. MDF's workability and higher range of thicknesses make it perfect for detailed furniture and architectural work.

Neither material suits outdoor use or direct water contact. Both contain formaldehyde-based resins and require proper dust extraction during machining.

Where each material excels

Many projects benefit from using both materials strategically. Kitchen cabinets might use MDF for the painted carcasses where workability matters, whilst using HDF for door panels that need extra durability.

Working with each material

MDF machines beautifully with standard woodworking tools. It cuts cleanly, routs well and accepts detailed profiles without chipping. HDF requires more care, its density means tools work harder and need more frequent sharpening.

The best tools to use

For MDF

- Standard carbide-tipped saw blades work well

- Regular router bits handle most profiles

- Standard drill bits for pilot holes

- Edge sealing essential before painting

For HDF

- High-quality carbide blades with 60+ teeth

- Reduced feed rates to prevent burning

- Sharp router bits essential

- Pre-drilling recommended for screws

Finishing MDF & HDF

MDF excels for painted finishes. Its smooth, uniform surface takes primer and paint beautifully after proper edge sealing. HDF also paints well, though its denser surface may require different primer choices. Where HDF really shines is as a substrate for veneering or laminating.

- Both materials contain formaldehyde-based resins

- Always wear a dust mask when cutting or sanding

- Use dust extraction or work outdoors when possible

- Seal cut edges immediately to reduce emissions

HDF produces finer dust when machined, making dust control even more critical. Both materials benefit from immediate edge sealing to reduce formaldehyde emissions and improve moisture resistance.

Cost comparison

HDF typically costs 50-100% more than MDF:

Standard MDF

- Moisture resistant:£20-35/m²

- Available thicknesses:3-38mm

- Availability:Excellent

Standard HDF

- Premium grades:£35-50/m²

- Available thicknesses:3-8mm typically

- Availability:Limited

The cost difference reflects HDF's more complex manufacturing process, higher pressing pressures, finer wood fibres, and increased resin content all add to production costs.

For a typical kitchen project using 20 square metres of board, you're looking at roughly £300-500 for MDF versus £500-800 for equivalent HDF coverage. The premium often justifies itself in applications where durability matters - kitchen cabinet doors made from HDF typically last significantly longer than MDF equivalents.

Choosing the right board

Both HDF and MDF are excellent engineered wood products, each with its own strengths. Rather than viewing them as alternatives, think of them as complementary materials that excel in different applications.

HDF's density provides superior strength and moisture resistance, making it ideal for flooring substrates, door skins, and high-wear applications. Its limited thickness range and higher cost reflect its specialised nature.

MDF offers exceptional workability and takes paint beautifully, making it perfect for furniture, skirting boards, and detailed architectural work. Its wider range of thicknesses and lower cost make it the go-to choice for most woodworking projects.

Consider your specific requirements, the level of wear expected, whether detailed machining is needed, your budget constraints, and the tools available. This will guide you to the material that best suits your project's needs.