Best Adhesives For Skirting Boards 2025 | Free Delivery | Bulk Buy

Posted by Skirting World on 2nd Jan 2025

Fixing skirting boards to the wall is the most vital finishing step in the skirting board installation process.

Most skirting boards are fixed solely with grab adhesive or in addition to nails / screws. But some adhesives are better than others, and your skirting boards might benefit from an adhesive with particular properties.

We've been in the skirting board manufacturing industry for over 10 years and in that time we've curated a tried and tested selection of adhesives for skirting boards. Keep scrolling to learn more.

The Best Skirting Board Adhesives

1. Demsun A32 Express Adhesive

Here at Skirting World, we stock a fair few products from Demsun because they're top quality and get the job done.

This definitely applies to the A32 Express Adhesive in the number one spot.

The word 'express' within the title points to its super quick curing time of just 15 minutes!

It has a strong grab and is also flexible, so it has everything you should be looking for!

| Demsun A32 Adhesive: Technical Properties | ||

|---|---|---|

| Properties | Value | What this Means |

| Basis | MS Polymer | Combines silicone & polyurethane properties for strong, flexible bonds. |

| Density | 1.49 ± 0.03 gr/ml | Thick & concentrated adhesive. |

| Tack-Free Time | 15-20 min (23°C and 50% R.H.) | Dry to touch in 15-20 minutes (ideal conditions). |

| Shrinkage | Approx. 3.5 mm/24 hr (23°C and 50% R.H.) | Considers slight shrinkage during curing. |

| Pressing Time | 0 mm | Forms strong bond without external pressure. |

| Temperature Resistance | +5 °C to +35 °C | Maintains performance in moderate temperatures. |

| Application Temperature | +5°C and +40°C | Use between +5°C and +40°C for optimal bonding. |

2. Demsun A30 Adhesive

The A30 Adhesive from Demsun is another solid choice. This has been the skirting board adhesive of choice for most of our customers since we started stocking it.

Essentially, it's a slightly cheaper version of the A32 as it doesn't cure as fast.

However, if you're not in a rush it's a more than ideal adhesive to do the job.

| Demsun A30 Adhesive: Technical Properties | ||

|---|---|---|

| Properties | Value | What this Means |

| Basis | Acrylic dispersion | Water-based, fast-curing with clean bond. |

| Density | 1.40 ± 0.03 gr/cm³ (ASTM D 1875) | Relatively high density adhesive. |

| Tack-Free Time | 30-40 minutes (at 25°C and 50% R.H.) (ASTM C 679) | Dry to touch in 30-40 minutes (ideal conditions). |

| Curing Rate | 1-2mm/day (at 25°C and 50% R.H.) | Reaches full strength gradually over a day. |

| Temperature Resistance | -10°C to +80°C | Durable bond in moderate to warm temperatures. |

| Application Temperature | +5°C to +40°C | Use between +5°C and +40°C for best results. |

| Maximum Shear Strength (beech-beech) | > 40kgf/cm² (after 6 hours), > 70kgf/cm² (after 24 hours) | Strong bond (>40kgf/cm²) after 6 hours, even stronger (over 70kgf/cm²) after 24 hours. |

3. CT1 Sealant & Adhesive

CT1 Sealant and Adhesive stands out as a champion in versatility. It consistently impresses with its capabilities and wide range of applications.

While CT1 might carry a slightly higher price tag compared to some other options, its unmatched versatility makes it a true value. Unlike many sealants and adhesives, CT1 tackles a wider range of surfaces, both indoors and outdoors. This eliminates the need for multiple products for different tasks.

| Parameter | Details | What this means |

|---|---|---|

| Application Temperature | +5°C to +40°C | This is the temperature range in which you can apply the product. It is suitable for most moderate climates. |

| Flow/Sag | < 3mm | Indicates minimal sagging or movement after application, ensuring it stays in place. |

| Skin Cure (23°C 50% R.H.) | 25 minutes ±5 min | The time it takes for the surface to dry to the touch, making it tack-free. |

| Full Cure Time (23°C 50% R.H.) | 2-3mm/12hrs | The time required for the product to fully harden at various thicknesses. It cures faster for thinner applications and takes longer for thicker ones. |

| Density (ISO 1183-1) | 1.58kg/Ltr | The mass per unit volume, indicating how heavy it is. |

| E-Modulus 100% | 1.15 N/mm² | Measures stiffness. Higher values indicate a stiffer material. |

| Volume Shrinkage After Cure | < 3% | The amount it shrinks after curing, ensuring stability and minimal deformation. |

| Hardness (DIN 53505) | 55° Shore A | Indicates resistance to indentation, useful for determining durability. |

| Tensile Strength | 290 N/mm² (2.90 Mpa) | The maximum stress it can withstand while being stretched or pulled. Higher values indicate stronger material. |

| Thermal Stability | -40°C to +120°C | The temperature range it can withstand without degrading, suitable for extreme conditions. |

Need big? Buy CT1 in bulk to save big!

3. Demsun P88 Multi-Purpose Foam

Many in the trade have praised the adhesive qualities of expanding foam. We can't claim that this works as we have yet to try it, but there are plenty of tradesmen using it with great results.

The basics of using foam to stick skirting boards to the wall are as follows:

- Mist the surface with water (not the skirting, just the wall).

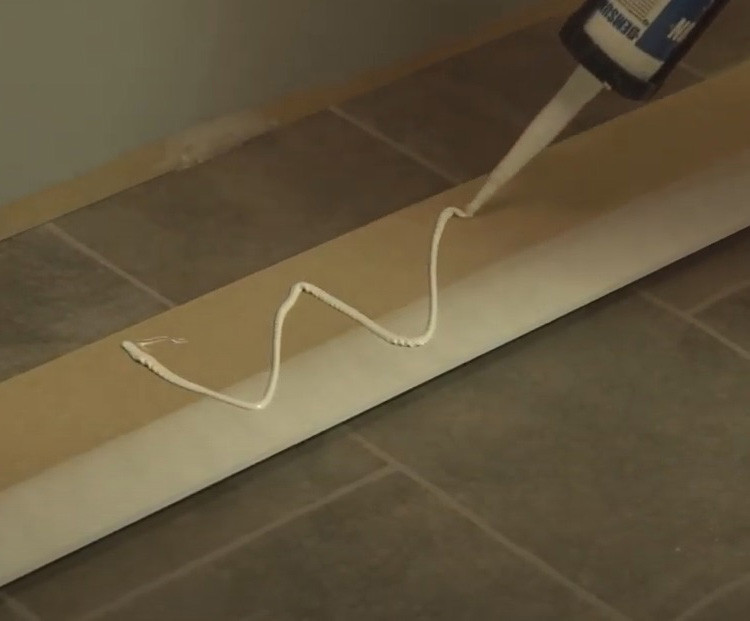

- Apply a couple of neat beads of foam to the skirting using a foam gun.

- Offer it up to the wall and secure it with something heavy for around 10 minutes.

That's pretty much it! You should now have skirting that is fixed to the wall using expanding foam. And according to many online, this method offers as strong a bond as any skirting board adhesive they've used.

Benefits include super easy removal when required. Simply sliding a thin metal ruler (or a breadknife) between the skirting and the wall should break the foam and allow the board to come away from the wall.

This prevents damage to the plaster, no mess to clean up and the boards can be put back on the wall as easily as they came off.

Even though the removal with this method is easy, don't think that this means the hold strength of the foam isn't as good as the adhesive. According to many that use this method, once the foam is set there's no chance of the skirting coming off without breaking the foam.

Most have also stated that a general expanding foam will do - no need to look for a specialist product. And they also say that you must use the foam with a foam gun for the best control.

According to one user, thermal and sound insulation seem to be improved by using foam as an adhesive too.

Demsun A36 MDF Mitre Bonding Kit

Creating perfect mitre joints on your skirting boards requires a strong adhesive to ensure a lasting and professional finish. If you're working with MDF skirting, consider the MDF Mitre Bonding Kit like Demsun A36, formulated for fast-acting bonds on MDF. For most wood skirting boards, a strong wood glue or a versatile option like CT1 Sealant & Adhesive will do the trick. Remember to factor in drying time when choosing your adhesive – faster drying options might be ideal if you're looking to expedite your project.

| Demsun A36 Mitre Bonding Kit: Technical Properties | ||

|---|---|---|

| Properties | Value | What this Means |

| Basis | Ethyl Cyanoacrylate | Super glue for fast curing & strong bonds. |

| Appearance | Liquid gel | Gel consistency for precise miter joint bonding. |

| Color | Colorless | Maintains natural material appearance. |

| Application Temperature | +5°C to +35°C | Use between +5°C and +35°C for optimal bonding. |

| Density | 1.06 ± 0.01 gr/cm³ ASTM D1875 | Relatively low density adhesive. |

| Flashpoint | > 81°C | Low flammability risk. |

| Viscosity | 1200 - 1800 Cps at 25°C ASTM D1084 | Moderately thick gel for gap-filling. |

| Temperature Resistance | -20°C to +70°C | Maintains strong bond between -20°C and +70°C. |

3. Gripfill

Before we found Demsun, we used to stock Gripfill from Evostik.

Therefore, we can recommend this adhesive for securing skirting boards.

However, our Demsun alternatives are the best options and we normally have plenty in stock!

What To Look For In A Good Adhesive

There's an abundance of skirting board adhesives on the market, so exactly what should you be looking for?

There are certain qualities that you'll want to ensure the chosen glue has.

1. Grab

Arguably, one of the most important factors is the 'grab'. This is basically how strongly the glue sticks to a surface.

A very strong grab is needed in a skirting board adhesive for skirting boards to ensure they stay put and don't start to come away from the wall over time.

2. Curing Time

Curing time is also another one to look out for. When gluing skirting boards, it's best to go for a skirting adhesive with a fast curing time. This means that it will set quickly, removing the need to hold it in place whilst the glue goes off.

3. Flexibility

Making sure the skirting board adhesive you choose is flexible will ensure it stands the test of time.

Choosing a non flexible adhesive will no doubt cause issues down the line. It will eventually become brittle and weakened. This is bad because skirting boards can expand and contract as temperature and moisture levels change within a home.

It's also wise to make sure the skirting board adhesive is flexible due to vibrations from foot traffic which simply cannot be avoided.

4. High Gap Filling Properties

Almost all of the time, the back of the skirting board you will be applying adhesive to will be completely flat.

However, the same can't always be said for the walls where the skirting is getting fitted. Unless it's freshly plastered, there may be holes / cracks present which can cause an issue with the skirting board adhesive being able to bond.

Make sure the adhesive is capable of filling gaps. This ensures that the skirting board adhesive can fill any of the gaps present on the wall when you apply the skirting. This will prevent weak spots when the skirting adhesive has cured.

Surface Preparation

No matter how good your skirting board adhesive is, it won't work as well as it should if you don't take the time to prepare the surface it will adhere to. A poorly prepared surface will be a weak adhesion point.

Before applying any of the skirting board adhesive, ensure that the skirting board and wall are free of debris, dust and grease as these will hinder the performance. The end result will be a much stronger and longer lasting bond between the two surfaces.

When you're working on a wall that's not completely flat, try your best to make it as flat as possible. For example, a plaster wall may benefit from a light sanding to remove any lumps and bumps.

Remember, using an adhesive with high gap fill will help in this regard.